Top 5 IT Support Challenges in Manufacturing (And How AI Can Solve Them)

Modern manufacturing companies rely on technology more than ever to stay competitive, efficient, and innovative. However, this increased dependence on IT comes with its own set of challenges, from dealing with aging systems to protecting sensitive data from cyber threats, which can disrupt operations and limit growth if left unaddressed. In fact, even brief IT outages on the factory floor can cascade into delayed production schedules and missed delivery deadlines. One industry survey found that an hour of downtime can cost a company up to $300,000 on average, and in manufacturing that figure is often higher due to the scale of production. Clearly, minimizing IT issues and resolving them quickly is critical for manufacturers’ revenue and reputation.

An engineer uses a laptop amidst machinery in a manufacturing facility, illustrating how tightly integrated IT systems are with production processes.

In this post, we’ll explore the top 5 IT support challenges in manufacturing and discuss how AI-powered solutions can help overcome them. Each challenge is backed by current data and industry examples, and we’ll see how technologies like AI assistants, self-service platforms, and smart automation can make a tangible difference in keeping manufacturing operations running smoothly.

1. Legacy Systems and Outdated Technology

The Challenge: Many manufacturing plants still rely on aging infrastructure and legacy systems that struggle to keep up with modern demands. These outdated machines and software may be mission-critical, yet they are prone to failures and often incompatible with newer technologies. For example, a factory might be running production equipment on an old, unsupported operating system – leaving it vulnerable to security risks and hard to integrate with updated enterprise software. Legacy systems can create data silos and inefficiencies, as they don’t easily share information with newer platforms. Overall, clinging to outdated tech leads to frequent breakdowns, patchwork integrations, and rising maintenance costs, hindering a manufacturer’s efficiency.

How AI Can Help: AI can’t magically modernize old hardware, but it helps bridge the gap between legacy and modern systems. An AI-powered support assistant can be trained on documentation for older equipment and software, enabling it to quickly retrieve fixes and troubleshooting steps for legacy systems when issues occur. This means even if a particular legacy machine acts up, employees can ask an AI chatbot for immediate guidance (e.g. “What does Error Code 123 mean on Machine X?”) and get answers drawn from manuals or past cases – without hunting down a veteran technician. AI tools can also monitor legacy systems’ performance data for anomalies, alerting IT teams to impending failures. In essence, AI acts as a knowledge bridge, allowing manufacturers to continue leveraging legacy assets while minimizing downtime. Additionally, modern AI integration platforms can interface with older databases or applications, pulling their data into a unified view. This reduces the data silo problem and extends the useful life of legacy systems by augmenting them with an intelligent layer. By providing quick support and partial automation around legacy technology, AI buys manufacturers time to upgrade on their own schedule, smoothing the transition to newer systems.

2. Escalating Cybersecurity Threats

The Challenge: Cybersecurity is a growing concern in manufacturing – and not just in office IT networks, but on the shop floor as well. Manufacturers have become prime targets for cyberattacks in recent years. According to an IBM study, over 25% of cyber incidents in the past year involved manufacturing companies, with ransomware attacks making up the majority. The interconnected nature of modern manufacturing (Industrial IoT sensors, production systems linked to corporate IT, supplier portals, etc.) means there are countless potential entry points for attackers. A single phishing email or malware infection can spread across production lines, bringing operations to a standstill. Beyond data theft, cyber incidents in manufacturing often cause physical downtime – machines halted, orders delayed – and can even lead to unsafe conditions or equipment damage. Yet many manufacturers are running outdated security protocols and may not have dedicated security staff on site, making them even more vulnerable.

How AI Can Help: AI is becoming a vital ally in the fight against cyber threats. On the preventative side, AI-driven security systems can analyze network traffic and user behavior in real time, detecting anomalies or suspicious patterns far faster than a human could. This means potential intrusions or malware can be identified and isolated before they wreak havoc on production. For example, AI-based monitoring might catch unusual PLC (programmable logic controller) commands or a spike in network traffic that suggests ransomware is spreading, and automatically alert IT to take action. On the support side, an AI assistant can educate and guide employees on security best practices. Many breaches start with a simple mistake (like an employee clicking a phishing email). An AI chatbot integrated into your support workflow can serve as a first line of defense – employees could ask, “Is this email legitimate?” and the AI, having been trained on phishing examples, can warn if it looks suspicious. AI-based self-service can also walk users through immediate steps if a security incident is suspected (e.g. isolating a infected machine, resetting passwords, etc.). This quick guidance can contain threats before IT personnel even arrive. Furthermore, AI can ensure consistent enforcement of security policies during support interactions. For instance, if an employee requests access to a system, the AI assistant will only provide information or execute steps that comply with security permissions and require multi-factor authentication if appropriate. By acting as a vigilant helper – from monitoring threats 24/7 to coaching users – AI reduces the risk of cyberattacks and helps limit the damage if one occurs. This is especially crucial in manufacturing, where a single breach can halt production and cost millions.

3. Unplanned Downtime and Slow Issue Resolution

The Challenge: In manufacturing, downtime is the enemy. When critical IT systems or equipment go down unexpectedly, every minute of halted production translates to lost revenue. Studies show that downtime can cost a manufacturer around $260,000 per hour on average – a staggering figure that underscores how high the stakes are. Causes of downtime range from server/network failures (e.g. a crashed ERP system) to machinery malfunctions that require IT support for diagnostics. The challenge is not just that failures happen, but that traditional IT support may not respond quickly enough. Many manufacturing IT departments operate during business hours only, or are understaffed, meaning if a line goes down at 2 AM or on a weekend, it stays down until help is available. Even during the day, if support tickets take hours to triage and resolve, that delay is extremely costly in a factory setting. In short, slow response and resolution times exacerbate downtime, and every extra minute offline hurts. This can also lead to missed shipping deadlines and frustrated customers. Uptime is so critical that manufacturers view reliable IT support as indispensable. How can we ensure issues are fixed faster?

How AI Can Help: This is where AI really shines: speeding up detection and resolution. AI-powered monitoring systems can watch over IT infrastructure and equipment sensors continuously, often predicting or flagging issues before they cause a full shutdown. For example, AI-based predictive maintenance can analyze machine data to foresee when a part is likely to fail, so it can be replaced proactively before it breaks and halts production. But even when unexpected problems do occur, an AI support assistant can provide instant first response. Unlike a human team that might be unavailable at night or swamped with other calls, an AI chatbot is available 24/7. The moment an operator encounters a software error or a device failure, they can describe the issue to the AI (via a chat in their mobile device or console) and get guided troubleshooting immediately. This instant response can reduce that initial waiting time from potentially hours to literally seconds. In fact, real-world cases have shown that AI support platforms can cut first response times by over 90% – one company saw their average response drop from 15 minutes to just 23 seconds with an AI-driven system. Faster response is paired with faster resolutions: AI can often resolve common incidents on the spot by running through scripted diagnostics or providing step-by-step fixes for known problems. For instance, if a production database service stops, the AI assistant could automatically attempt a restart or guide an on-site technician through rebooting a specific server. By some estimates, modern AI agents can auto-resolve 40–60% of routine support tickets without human help. All of this means downtime is shortened dramatically. Even when the AI cannot fix an issue fully, it accelerates the process by collecting relevant information and escalating directly to the appropriate human expert with context. There’s no time lost figuring out basics because the AI has already run preliminary checks. In sum, AI-driven support ensures that manufacturing operations get back online faster, saving potentially hundreds of thousands of dollars and preserving customer trust. When every minute matters, having an tireless virtual assistant on standby can make a world of difference in uptime.

4. Limited IT Support Staff and Skills Gaps

The Challenge: Many manufacturers operate with lean IT teams or even no dedicated IT staff on-site, especially in small-to-mid size plants. Even larger operations might struggle to hire specialists who understand both IT and operational technology (OT) – a niche skillset. In fact, the manufacturing industry at large is grappling with a workforce skills gap: 74% of industrial companies report an acute shortage of skilled workers, and a majority are looking to upskill or hire to fill that gap as they adopt smarter technologies. Within IT support, a limited headcount means each person is juggling many tasks and may not be available whenever an employee needs help. A production line worker could be waiting while the single IT manager is busy elsewhere. This resource constraint is exacerbated by location and shift work – one IT team might be responsible for multiple facilities, or there might be no coverage during nights. As a result, issues wait in queue and employees can’t get timely help to do their jobs. Moreover, not every IT department in manufacturing has expertise in all the systems in use (think of specialized CAD software or PLC programming tools). The shortage of knowledgeable support leads to slower fixes or having to call expensive external consultants. Ultimately, limited in-house IT resources can significantly hinder operations. If minor problems pile up or go unresolved, it drags down productivity across the board.

How AI Can Help: AI acts as a force multiplier for stretched IT teams. It allows a small support staff to punch above their weight by offloading a huge chunk of routine work to automation. For example, an AI helpdesk agent can handle the common questions and tasks that would otherwise eat up hours of a human technician’s day – things like password resets, software installation guides, VPN troubleshooting, Wi-Fi connectivity issues, and so on. Industry research shows that 20–50% of all help desk requests are simple password resets alone. Rather than your limited IT staff spending half their day on such mundane tickets, an AI chatbot can securely handle password reset workflows (verifying the user and initiating the reset process) within seconds. This automation frees up the human techs to focus on more complex or strategic projects. In general, companies adopting AI-driven support report a significant efficiency boost: AI can auto-resolve up to 80% of routine queries and issues, dramatically reducing the support burden on staff. By deflecting repetitive tasks, even a one-person IT department can effectively provide 24/7 coverage with the AI handling inquiries round the clock. Another benefit is that AI never gets overwhelmed – it can scale to support hundreds of employees simultaneously, something a small team cannot. So as the company grows or faces bursts of demand, the AI can absorb the extra load. This scalability is cost-effective; instead of hiring multiple additional technicians (which could be difficult due to the skills shortage and budget constraints), deploying an AI assistant has a relatively fixed cost. In fact, automation with AI has led to a 30% decrease in IT support operating costs on average, and up to 90% reduction in labor costs for certain tasks. Beyond handling volume, AI also helps with the skills gap issue: it encodes expert knowledge that your team might not possess, ensuring that even niche questions get accurate answers. For instance, if your lone IT person isn’t an expert in a legacy CNC machine software, the AI can be trained on the vendor docs and step in to assist an operator’s question. Overall, AI augmentation means faster support without adding headcount. Your human experts are less overloaded and can concentrate on high-value issues (or strategic improvements) while the AI takes care of the rest. In a manufacturing environment where hiring additional qualified IT staff is challenging, AI support can truly be a lifesaver – maintaining service quality and responsiveness even with a small team, and effectively narrowing the skills gap through instant, knowledge-rich assistance.

5. Lack of Self-Service and Knowledge Accessibility

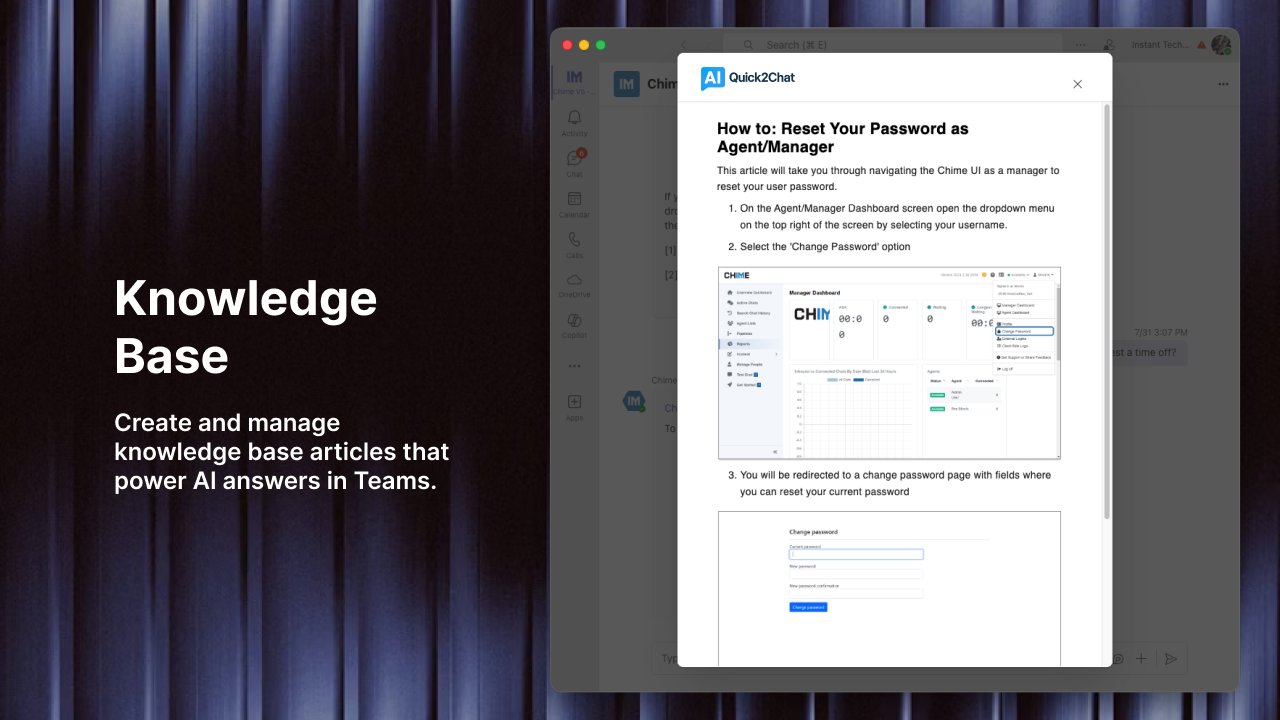

The Challenge: When employees on the manufacturing floor or in the office have an IT problem, do they have a quick way to find a solution on their own? In many companies, the answer is no – every issue, no matter how minor, ends up requiring a call or ticket to IT. This lack of self-service options and easily accessible knowledge is a significant challenge. It creates a frustrating experience for users (nobody likes waiting on hold for the help desk to answer a basic question) and also balloons the support workload for IT staff, as they must repeatedly solve the same common issues. Important troubleshooting knowledge often resides in scattered documents or in the heads of veteran engineers, rather than in a centralized, user-friendly knowledge base. The result is a knowledge silo: employees might not even know that a solution exists in a document somewhere, so they default to asking IT for help. This not only slows down resolution, but sometimes employees won’t bother asking at all – instead, they might try ad-hoc fixes or use unauthorized “shadow IT” tools to work around the problem. Shadow IT (when workers use unapproved apps or devices because the official support is too slow or rigid) introduces security and compliance risks. Clearly, empowering users with better self-service could alleviate many of these issues. And indeed, there is evidence that employees want self-service: one survey found 31% of employees prefer digital self-service to contacting IT support for difficult problems, and another 27% would prefer a mix of self-service first, then human help if needed. That means well over half of your workforce would happily try a self-help solution before calling the helpdesk, if only it existed. Yet many manufacturing firms haven’t implemented modern self-service portals or AI knowledge bases. This is a missed opportunity to improve satisfaction and efficiency.

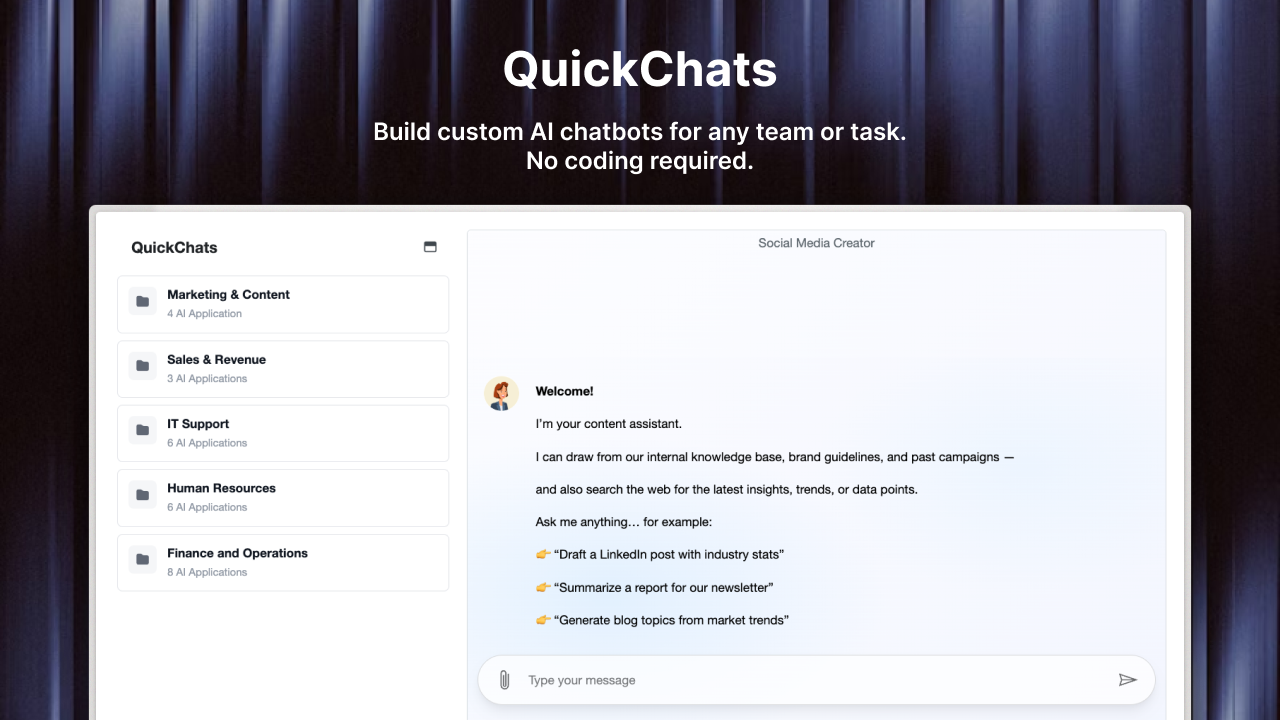

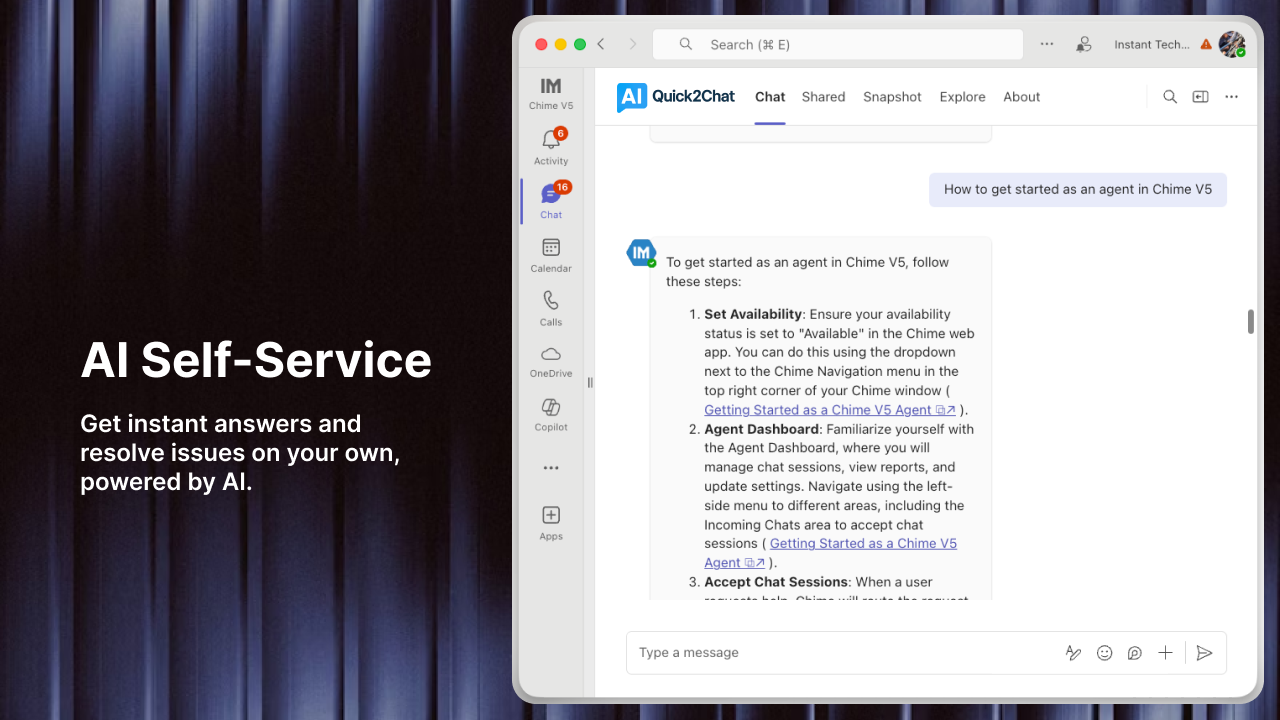

How AI Can Help: AI is the key to unlocking effective self-service in IT support. A well-designed AI chatbot can act as a virtual concierge for all employee IT questions, available instantly through a chat interface. Instead of filing a ticket and waiting, an employee could simply message the AI assistant (for example, through Microsoft Teams or a web portal) with something like, “My badge login isn’t working on the assembly station PC” or “How do I install the latest CAD software update?” The AI, connected to a vast knowledge base of troubleshooting guides, FAQs, and company-specific fixes, will immediately respond with relevant information or step-by-step instructions. This satisfies the user’s need on the spot in many cases. In fact, 91% of users say they would use an online knowledge base if it’s tailored to their needs, indicating that people are very open to self-service when the content is helpful. AI makes that content easy to query with natural language and can even walk the user through complex procedures interactively. For example, the AI could guide an employee through a printer calibration or a machine reboot sequence, one step at a time, asking questions in between to refine the solution. By deploying an AI self-service tool, manufacturers empower their employees to solve many problems on their own, within minutes, at any time. This not only boosts productivity (less waiting around) but also dramatically reduces the ticket volume hitting the IT team. As Atlassian noted, when employees have good self-service, they end up dealing directly with IT support far less than half the time. Moreover, AI self-service can personalize answers based on context. It might know the user’s role, the equipment they work with, or their permissions, and tailor the solution accordingly – something static FAQ pages can’t easily do. And importantly, if the AI cannot solve an issue (maybe it’s truly novel or critical), it seamlessly escalates to a human agent, transferring all the details it has gathered so far. This “human handoff” ensures that self-service never becomes a dead end; instead it handles what it can and hands off what it can’t. The integration of AI with ticketing systems means even escalations are logged as tickets with full context, so nothing falls through the cracks. Finally, by capturing frequent queries and solutions, the AI continuously helps build a better knowledge base (following knowledge-centered support practices). Over time, this creates a virtuous cycle: the more you use AI for support, the smarter and more comprehensive your self-service knowledge becomes. In short, AI-driven self-service breaks down knowledge silos and puts answers directly into the hands of those who need them. Manufacturing employees get the help they need faster and with less hassle, and the IT team benefits from fewer simple tickets and more time to focus on complex projects. It’s a win-win that improves both user satisfaction and support efficiency.

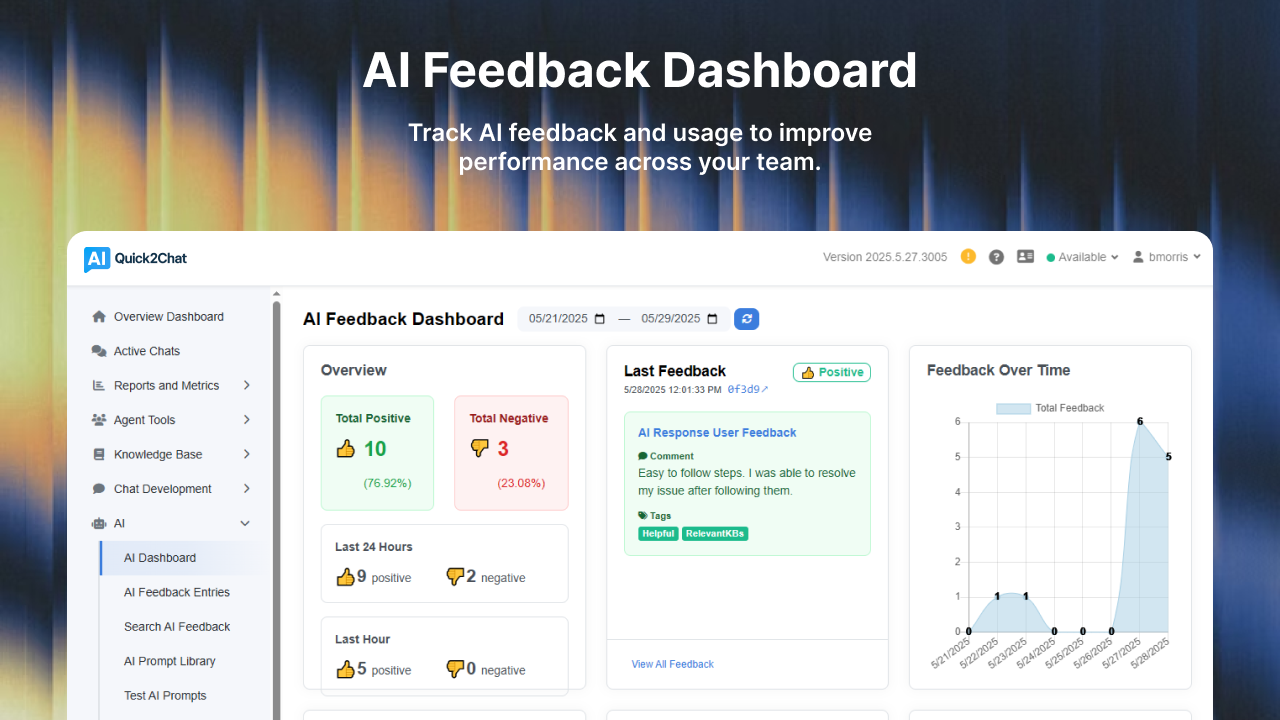

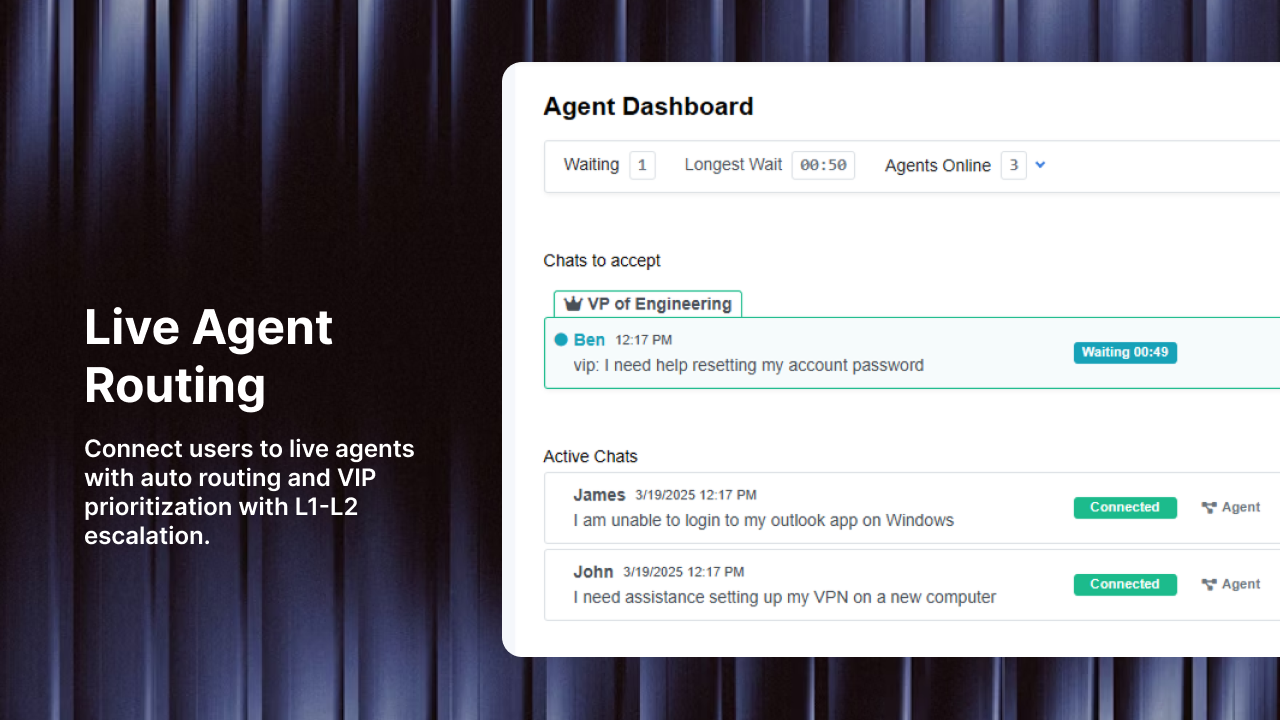

Transforming IT Support with AI: How Quick2Chat Can Help

All of the above challenges – from legacy system woes to after-hours downtime – can be addressed with the right AI tools. Quick2Chat is a cutting-edge AI support platform (available via web and Microsoft Teams) designed specifically to help companies overcome these IT support hurdles. It brings together the power of conversational AI, automation, and integration in one easy-to-use solution. By deploying Quick2Chat in your manufacturing organization, you can quickly realize the benefits discussed throughout this post:

· 24/7 AI-Powered Assistance: Quick2Chat’s intelligent chatbot is available around the clock to answer questions and troubleshoot issues. Your employees can get instant help at 2 PM or 2 AM, which greatly reduces waiting time and unplanned downtime. The AI uses natural language understanding to handle requests conversationally, providing fast, relevant responses any time they’re needed.

· Self-Service Knowledge at Your Fingertips: Quick2Chat connects to your IT knowledge base, FAQs, and documentation so that employees can resolve common problems on their own. The AI will guide users step-by-step through solutions (like connecting to the secure Wi-Fi or resetting a machine interface) without involving a human agent. This empowers staff and deflects a huge volume of simple tickets away from your busy IT team.

· Seamless Human Handoff: If an issue is too complex for the AI or requires human judgment, Quick2Chat knows when to escalate. It can hand off the conversation to a live IT support person through Microsoft Teams or your ticketing system, including all the context and logs of the interaction so far. This ensures a smooth transition with no time lost, and the user never has to repeat themselves. Your IT staff can then focus only on the trickier issues, with the AI handling the front-line triage.

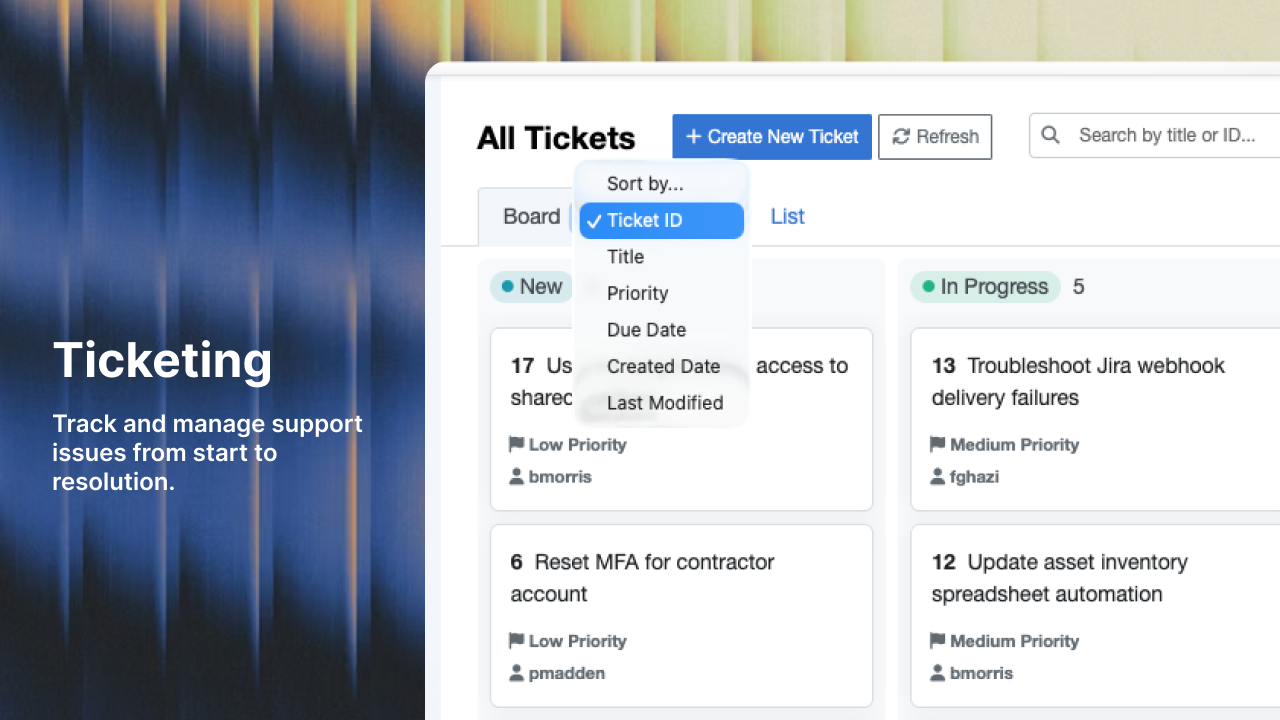

· Ticketing System Integration: Quick2Chat integrates with popular IT Service Management (ITSM) and ticketing platforms (such as ServiceNow, Jira Service Management, etc.). This means the bot can create, update, and close tickets automatically as it interacts with users. For example, if a user asks the bot for help with a software crash, the bot can log a ticket, try known solutions, and if it fixes the issue it will mark the ticket resolved – all without manual intervention. For escalations, it assigns the ticket to the right team. This integration ensures every issue is tracked and nothing falls through the cracks, while saving your team time on manual data entry.

· Microsoft Teams Integration: Quick2Chat is natively integrated into Microsoft Teams, which is a huge plus for manufacturing companies that use Teams for internal communication. Employees can simply chat with the “Quick2Chat” bot within Teams on their PC or mobile device – no need to switch to a separate portal or make a phone call. This “support where you work” approach makes it incredibly convenient for frontline workers and office staff alike to get help. Whether they’re on the factory floor with a tablet or at a desk, assistance is just a Teams message away.

Quick2Chat brings AI and human support together in a unified solution tailor-made for enterprise needs. By adopting an AI assistant like Quick2Chat, manufacturing IT managers can tackle their top support challenges head-on: the AI will speed up response times, reduce downtime, improve knowledge sharing, bolster security practices, and extend the capabilities of your limited IT staff. The end result is a more resilient and efficient operation – employees get the help they need faster, systems stay up and running longer, and the IT team can focus on strategic improvements rather than firefighting everyday issues.

Manufacturing firms that leverage AI-driven support are seeing significant improvements in both productivity and cost savings. The technology is mature and ready to deploy. Don’t let IT support challenges hold back your manufacturing excellence. By investing in an AI solution like Quick2Chat, you equip your organization with a scalable, always-on support system that keeps pace with the demands of modern manufacturing.

Interested in learning more? Visit our website at Quick2Chat.com to see how our AI-powered assistant can be customized to your environment. Empower your team with instant support, and let Quick2Chat handle the heavy lifting of routine IT issues. It’s time to reduce downtime, boost employee satisfaction, and drive your manufacturing operations to new heights with the help of AI. Your production lines and your bottom line will thank you!

Sources:

-

Verity IT – "Top IT Challenges Facing Manufacturing Companies (And How to Overcome Them)"

-

Be Structured – "24/7 IT Support for Manufacturing: Maximizing Uptime and Productivity"

-

IBM Security – IBM X-Force Threat Intelligence Report (manufacturing as top attacked industry)

-

Aberdeen Research – Downtime Costs in Manufacturing (cited via Verity IT)

-

Desk365 – "AI Customer Service Statistics in 2025" (AI chatbot automation rates)

-

Pylon (AssemblyAI Case Study) – "How AI-Powered Support Reduces Response Times"